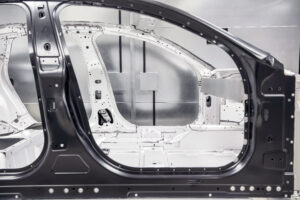

Polestar has confirmed that the forthcoming Polestar 5 electric performance 4-door GT will feature a brand-new, bespoke, bonded aluminium platform.

Bonded aluminium is lightweight and rigid, offering better performance and environmental advantages. While this technology has previously proven labour-intensive and difficult to use in mass production vehicles without sacrificing quality, Polestar’s 280-strong team of engineers, working in the Midlands, have resolved this challenge by developing an entirely new, faster manufacturing process that develops both body and platform in unison.

As a result of the new materials and techniques involved, the body-in-white (completed platform and body) is expected to weigh less than that of cars in smaller segments, contributing to improved vehicle efficiency, real-world EV range and dynamic responsiveness, all while delivering leading safety levels. The new bonded aluminium platform will also help drive faster product introduction, high quality and platform rigidity.

Get our FREE ‘GUIDE TO THE BEST EVs’ e-mailed directly to your inbox

“Our UK R&D team is one of Polestar’s greatest assets,” says Thomas Ingenlath, Polestar CEO. “Their mix of engineering and technological expertise enables us to develop advanced, lightweight sports car technology with a creative mindset and a spirit that embraces innovative engineering. This will set Polestar apart in the years to come.”

By further developing this technology for Polestar’s first in-house platform, the 4-door Polestar 5 is being designed with torsional rigidity superior to that of a traditional two-seat sports- or supercar. The decision to develop a bespoke platform has also enabled the brand to deliver a production model that remains true to the Precept concept car that inspired it.

“We knew we wanted this car to be lightweight, we knew we wanted high quality and we knew we wanted it quickly,” says Pete Allen, Head of Polestar UK R&D. “This architecture delivers outstanding dynamic and safety attributes, with low investment technology applicable to high production volumes.”

Development of Polestar 5 continues at pace, with global efforts led by a growing UK R&D unit, which is expected to grow to approximately 500 engineers in the coming months and will continue to play a critical role in enhancing Polestar’s in-house R&D capabilities. More details on Polestar 5 will continue to surface as the YouTube documentary series “Precept: From Concept to Car” details how the Polestar Precept evolves into the production car.

This announcement continues to strengthen Polestar’s position ahead of its proposed business combination with Gores Guggenheim, Inc. (Nasdaq: GGPI, GGPIW and GGPIU), which is expected to close in the first half of 2022.